-

ENGINEERING (R&D)

-

PROTOTYPES

-

PRODUCTION TOOL DESIGN

-

PRODUCTION TECHNOLOGIES

-

ASSEMBLY AND COATING

-

LOGISTICS

ENGINEERING (R&D)

Good coordination between the customer and a multidisciplinary project team, with experience and technical resources, is the best guarantee for the successful completion of a project.

Together with our customers, our team researches, develops and seeks innovative solutions that enhance the product value throughout the entire chain, always aiming to meet the customer’s needs and driving continuous improvement of the process.

PROTOTYPES

The development of new products is key to staying competitive in the market, which is why validating the process with prototypes often leads to significant savings in both time and money.

At the customer’s request, our development department will create the necessary tools so that, in a short period of time and at a low cost, the customer can obtain parts to test, adjust and validate the product before starting construction on the final tooling.

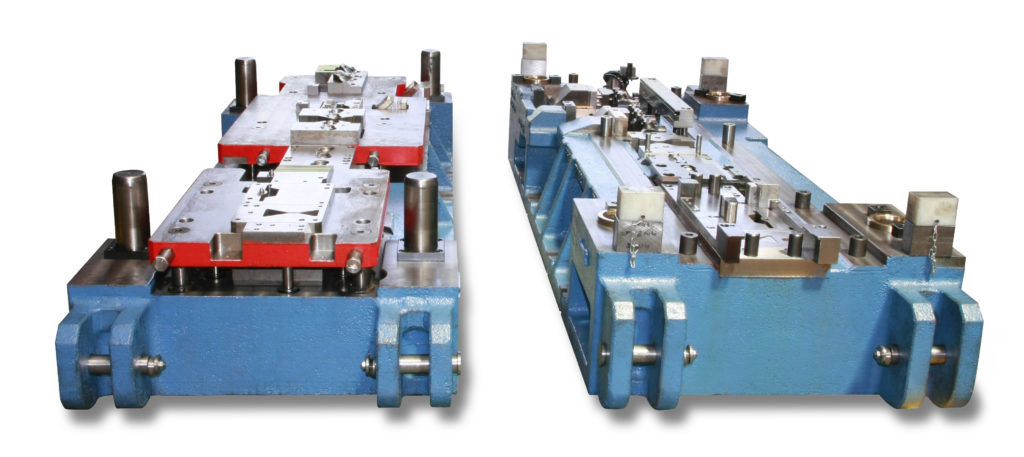

PRODUCTION TOOL DESIGN

We have our own tooling development workshop.

Modern machinery with worktables of up to 4000 mm, state-of-the-art wire erosion machines. All supported by CAD/CAM units, and combined with the know-how acquired over the years by our designers and toolmakers, allows us to offer highly precise tooling.

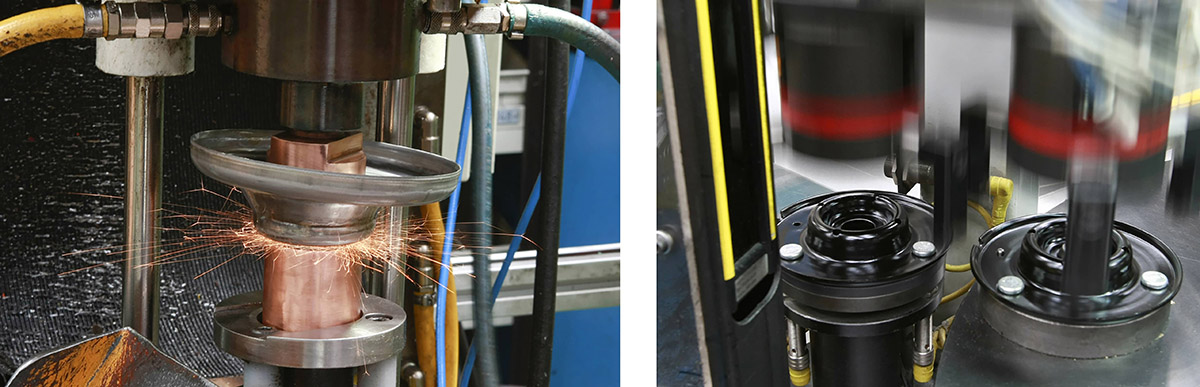

PRODUCTION TECHNOLOGIES

Stamping of parts using progressive, transfer, and conventional dies for small, medium, and large series.

Materials:

- Cold-rolled or hot-rolled steel

- Galvanized steel

- Aluminum

- Stainless steel

- High-yield-strength steels

- Ongoing development of third-generation materials

Forming Technology:

- Mechanical press lines up to 800 tons

- Hydraulic press lines up to 1,200 tons

- Robotized cells

Thicknesses from 0.5 to 6 mm.

Strip width up to 1,200 mm.

ASSEMBLY AND COATING

- Subassembly welding using resistance welding, TIG-MIG, and brazing

- Automated cells for subassembly mounting with 100% control of critical dimensions

- Precision machining using lathes and machining centers

LOGISTICS

From our Zaldibar center, we supply parts to more than 27 plants across five continents.

Using JIT manufacturing, the Kanban system, or consignment warehouses, we provide customers with what they need, when and where they need it, ensuring complete satisfaction throughout the process.

Contact:

calle Euskalerria s/n

48250 Zaldibar (Bizkaia) Spain

phone: ++34 946 827 364

fax: ++34 946 827 693

e-mail: infor@irudi.es

Sustainability rating

Associate

Copyright © 2023 All rights reserved.